1. Resistive strips, cold-rolled

QUALITY:

- ALKRAL® S (K) ρ: 1,25 ± 5% Ω mm²/m

- ALUTERM® ρ: 1,4 ± 5% Ω mm²/m

- AlSI310S (1.4845) ρ: 0,85± 5% Ω mm²/m

Chemical composition (in %)

ALKRAL® S (K)

| C max. | Cr | Al | Fe |

|---|---|---|---|

| 0,05 | 12 – 14 | 4 – 5 | balance |

ALUTERM®

| C max. | Cr | Al | Fe |

|---|---|---|---|

| 0,05 | 21 – 23 | 4 – 5 | balance |

AlSI310S (1.4845)

| C max. | Si max. | Mn max. | S max. | Cr | Ni | N max. |

|---|---|---|---|---|---|---|

| 0,1 | 1,5 | 2,0 | 0,014 | 24 – 26 | 19 – 22 | 0,11 |

Dimension

| ALKRAL® S (K) | width | 6 – 100 mm |

|---|---|---|

| thickenss | 0,2 – 2 mm |

| ALUTERM® | width | 10 – 50 mm |

|---|---|---|

| thickenss | 0,2 – 1,5 mm |

| AlSI310S (1.4845) | width | 10 – 100 mm |

|---|---|---|

| thickenss | 0,3 – 1,0 mm |

Heat treatment

- annealed

Slitting

- cut edges

Surface

- color golden brown

- silver (brushed)

Resistance tolerance of strip 1 m

ALKRAL® S (K)

- K – ± 3%

- S – ± 5%

ALUTERM®

- ± 5% / on demand

AlSI310S (1.4845)

- on demand

Delivery form

- coils (internal diameter of 400 mm) / on pallets

- cut lenghts / in packages

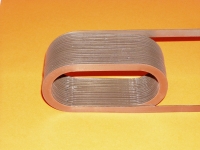

2. Production of edgewound coil

- round

- oval

3. Processing of customer´s material

- cold rolling

- slitting

- straightening and cutting into strips

- test strips, tensile strenght Rm(MPa), elongation A80(%)

- wire drawing KONSTANTAN) Ø 1,8 – 3 mm

4. Sales of electrical ceramics

- resistance saddles (porcelain)

- resistance rollers (porcelain)

- resistance rollers (kordierit)